Choosing the correct thread for your project starts with knowing the basic properties of thread and the options available. It can be overwhelming when you realize how many different types of thread are out there. The trick to thread selection is to choose the correct weight/thickness, fiber, and finish for your project. Generally speaking, All-Purpose Polyester thread works well for most general sewing projects. However, there are times when you may need to or may want to experiment with different types of thread.

We know it's confusing, which is why we’ve created The Ultimate Thread Reference Guide. It's the last thread reference you'll ever need. We hope this helps and that you can continue to use this article as a reference throughout your sewing journey.

Let's get started.

Thread is either animal-based, plant-based, synthetic, or a combination of those. In its simplest form, thread consists of two or more plies of "yarn" twisted together. It can either remain "soft" (untreated) or be treated with a special finish to increase its performance and appearance. A thread can be monofilament (basically, one long ply) or composed of multiple filaments (2 or more plies). Once it's spun, it's finished to accentuate project-specific features. It can be wax coated for shoemaking or silky smooth for low-lint quilting. It can even be finished with a vibrant, color-reflecting sheen, like quality embroidery thread.

Here are some of the terms you may come across:

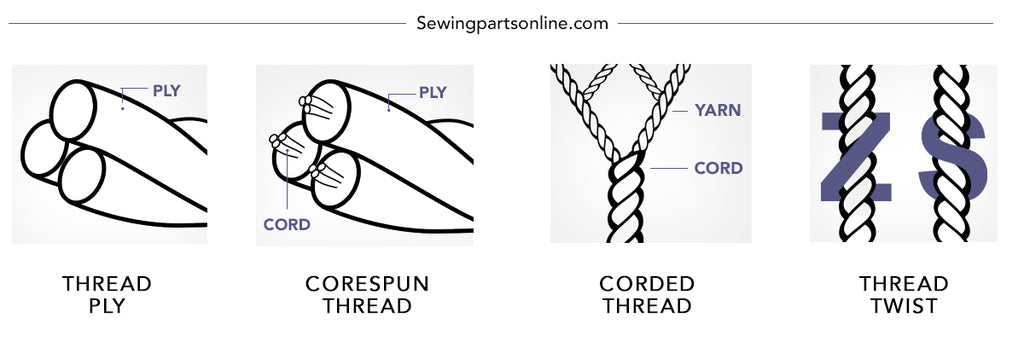

Cord: When multiple "threads" are twisted together, they create a "corded thread". These are commonly described as 4-, 6-, and 9-ply thread. As you can imagine, a corded thread will be stronger and thicker. You commonly see this used in leatherwork, shoe-making, etc.

Corespun Thread: This type of thread is composed of a "core" of continuous filament polyester that is wrapped with either cotton or polyester yarn, like a cocoon. These combined threads provide qualities from both fibers, with the outer fiber providing the finished “look”. For instance, a polyester core with wrapped cotton has the strength of polyester, but the finished look of soft cotton. This creates a stronger, more durable thread. You commonly see this type of thread used in the construction of Jeans.

Ply: This is basically a strand of yarn. You'll often see threads described as 2-, 3-, and 4-ply. The above image depicts a 3-ply thread.

Twist Direction: The direction the thread is spun defines its twist. It can either be twisted in a 'Z' direction (left twist) or a 'S' direction (right twist). A 'Z' twist is suitable for single needle sewing machines. An 'S' twist thread isn't commonly used in home sewing machines.

Thread Types

All-Purpose Thread: Your go-to, does-it-all thread. You’ll use this thread about 95% of the time. It’s acceptable for both hand and machine sewing. It's compatible with nearly all fabric (lightweight to heavyweight). This thread is usually made of polyester or cotton. It's not as heavy/thick as "heavy-duty thread", nor as thin/light as embroidery thread. It's perfect for constructing seams, edge stitching, quilting...it does it all. You wouldn't want to use this thread with very fine, sheer fabric or very heavy denim or canvas. It's not suitable for projects that will withstand constant, direct sunlight or very high heat.

Clear Thread: Also called Monofilament and Continuous filament thread, this type of thread resembles a very fine fishing line and is useful when you want your stitches to be invisible. Depending on the weight, you'll see monofilament thread everywhere from quilting to upholstery. Its nylon base makes it strong and able to withstand tension. Use clear on light fabric and the "smokey" tinted monofilament thread on very dark fabric. We recommend using a thread net and a metallic needle when machine sewing with clear thread.

Embroidery Thread: This term includes machine embroidery and hand embroidery thread/floss. Embroidery thread is made from a variety of fibers, rayon being the most popular due to its high sheen and affordability. Though rayon is very popular, polyester embroidery thread has made large strides and is now stronger and more "colorfast" than rayon. You can also find embroidery thread made of cotton and silk. Rayon and silk embroidery thread works well for lightweight and medium-weight fabric, but a heavier fabric should be embroidered with polyester embroidery thread.

Embroidery Floss: Popular for hand embroidery and needlepoint, embroidery floss is either spun by hand or by machine into 6 strands. It's then divided to achieve the desired thickness (when the user is ready to embroider). Colors, numbering, and weights vary depending on the manufacturer. Pay close attention to the thread fiber make-up to determine how it will perform on your fabric. If you're unsure, go by the feel of the thread and trust your judgment.

Elastic Thread: This type of thread is great for gathering and shirring fabric due to its high stretch and rebound. The trick to creating the most stretch is to hover your steam iron over the sewn elastic thread. Doing this will dramatically shrink the thread. By shrinking the thread, you create more gathers while still maintaining elasticity. After this, you can wash and dry normally without continued shrinkage.

Heavy Duty Thread: This thread is engineered to withstand high stress and tension. It comes in a variety of weights and finishes depending on what it's meant to sew. For example, a heavy-duty outdoor thread will be thick and resistant to UV rays and may contain water-resistant properties (depending on the manufacturer). Consider heavy-duty thread when sewing heavyweight fabric (like canvas or duck cloth) that will encounter a lot of wear and tear. Camping gear, luggage, and sports equipment are examples of projects that benefit from a heavy-duty thread.

Industrial Thread: Industrial machines are built to sew daily at faster speeds and for long hours. They can handle everything from chiffon to stacks of leather. "Industrial thread" is really a 2-part term; it can either describe the spool size (like a 5 lbs spool) or convey strength not found in the home-sewing realm (like Kevlar Thread). The industrial thread market is also where you can find the strongest, most durable, and most long-lasting thread. So, the term "industrial thread" can also mean "industrial strength", like the strength needed to sew firefighter's jackets, rock-climbing gear, and parachutes.

Jean Thread: This thread is designed specifically for sewing denim and is a little bit thicker than All-Purpose thread. Many manufacturers use corespun thread comprised of a polyester core wrapped in cotton. We recommend using a Jean Needle and choosing classic gold or blue-grey hues. You'll also find denim thread that is slightly variegated to blend in nicely with denim fabric when darning.

Metallic Thread: Metallic thread is used to embroider and sew decorative topstitching. It isn't very strong and breaks easily, which is why it needs the "white glove" treatment. It's usually made with a polyester core and wrapped with slivers of metal foil/tinsel. Do not use with high heat or steam, as it will weaken and destroy the stitches. When used properly, metallic thread is beautiful and is always worth the extra effort. Before you sew metallic thread, read our tips and tricks for sewing metallic thread.

Quilting Thread: Generally, quilting thread is either cotton, polyester, or a blend of both. Quilting thread is mercerized for increased strength and color longevity. It's gassed to reduce lint and designed to smoothly pass through the fabric without damaging it. Generally, you can use machine quilting thread for hand quilting as well. Popular quilting thread brands are Aurifil and King Tut.

Serger Thread: Overlock machines use 2 or more spools of thread to both construct a seam and/or finish the raw edge. To prevent bulk, serger threads are generally a bit finer than traditional sewing machine threads. Even though the thread may be finer, the end seam is still strong, durable, and flexible because it's composed of multiple threads (usually 3 or 4). Because so much thread is used, serger thread is wound on large cones with about 2,000 to 3,000 yards of thread. It's essential to buy high-quality serger thread, as lint builds up much faster than on your home sewing machine.

Textured Filament Thread: If you've ever used "wooly nylon", then you've used textured filament thread. It's highly elastic and soft. The texture component makes it appear thick and "fluffy" (if that makes any sense). It's also soft and has a luxurious sheen. It's commonly used in overlock machines for rolled hems. The thread provides excellent coverage so that the entire raw edge is hidden.

Upholstery Thread: This thread is used when upholstering furniture and comes in a variety of fibers and weights. It's stronger and more durable than All-Purpose thread. Upholstery thread is available in cotton, nylon, polyester, and silk. Nylon is commonly used because it has some "give", meaning it won't break every time someone sits on your reupholstered sofa. Many upholstery enthusiasts recommend matching the upholstery thread fiber with your fabric fiber. For instance, it's best to use silk thread for silk upholstery fabric. Upholstery thread and Heavy Duty thread are not necessarily the same, although you may see them used interchangeably.

Variegated Thread: This term describes a type of dyeing. The fibers are dyed in intervals of alternating shades and colors along the entire length of the thread. It's available in a variety of fiber variations and adds a great bit of energy and interest to both decorative stitching and utility stitching.

Waxed Thread: This thread is usually multi-filament and is coated with wax to give it water-repelling qualities. This type of thread is often used in industrial projects, like shoe-making. You may have also heard wax thread referred to as Awl Thread.

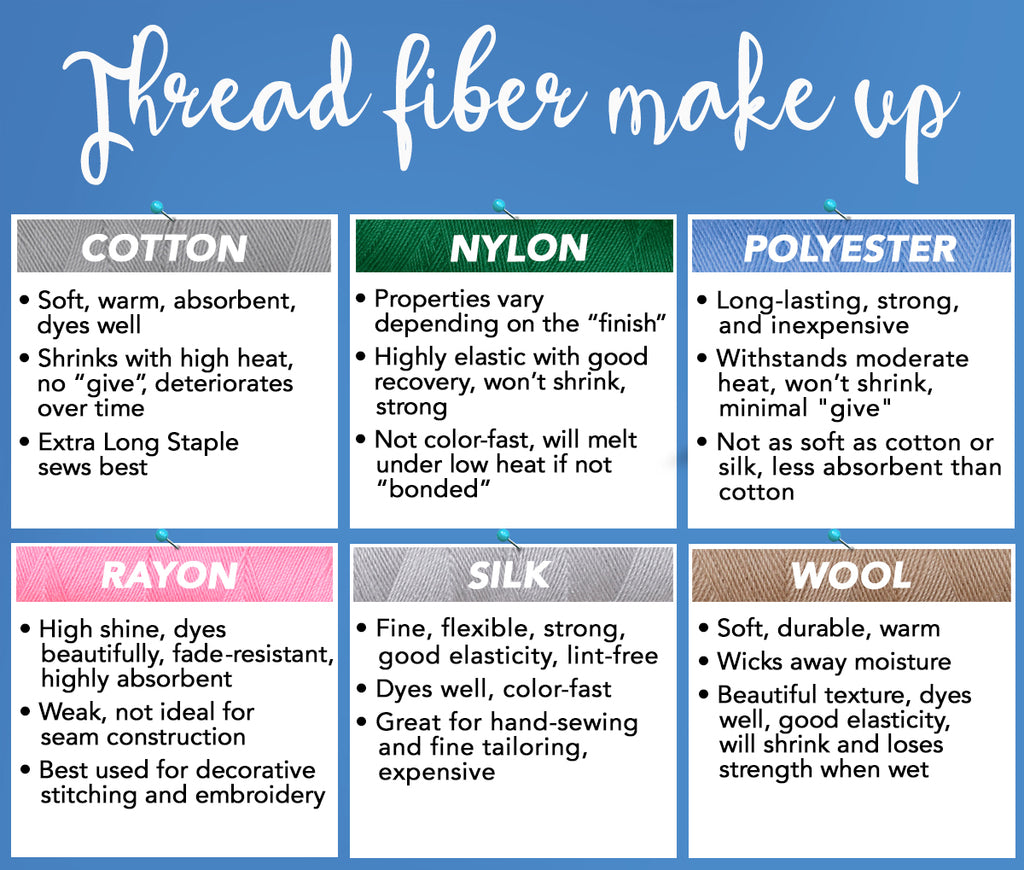

Thread Fiber Make Up

Polyester: Polyester thread is synthetic-based and is entirely man-made. It's low maintenance, durable, long-lasting, and relatively inexpensive. These qualities make it perfect for All Purpose Thread. It doesn't absorb moisture well and is able to withstand moderate heat. It can easily be engineered to resemble cotton, silk, and even nylon. It doesn't shrink and can accommodate a small amount of "give" with good recovery. However, it's a bit more abrasive than cotton and silk (you wouldn't want to use it on expensive silk chiffon).

Cotton: Cotton is soft, warm, and very absorbent. Cotton thread is derived from the boll of a cotton plant. Each boll contains approximately 250,000 fibers. These fibers, or staples, range in length from short (less than 1 1/8 inches), long (1 1/8 to 1 1/4 inches), and extra-long (1 3/8 to 2 inches). The longer the staple, the less lint it produces. Extra Long Staple Egyptian Cotton thread is considered the gold standard.

Cotton thread is great for sewing other plant-based fabric, like linen, cotton, and rayon. As long as you are using mercerized cotton, it shouldn't shrink like your cotton fabric (unless exposed to very high heat). Because it's highly absorbent, it dyes wonderfully. However, a Cotton thread has no “give” and breaks under high tension, as such, it’s not recommended for stretch fabric.

Rayon: Rayon is plant-based and is known for its beautiful shine and vibrant colors. It's not as strong as polyester and the manufacturing process is pretty bad for the environment, but it's inexpensive and comes from a renewable resource (wood pulp). It's also highly absorbent and fade-resistant. Many people use rayon for their embroidering, topstitching, and monogramming. We don't recommend Rayon thread for seam construction because it's not as strong as polyester and becomes even weaker when wet.

Nylon: This synthetic thread is relatively inexpensive and easy to use. It has good elasticity and doesn't shrink. Nylon melts easily (only use low setting when ironing), especially if it isn't "bonded'. Bonded Nylon is very strong and comes in a variety of weights. However, it doesn't hold color well and will yellow over time when exposed to sunlight (unless specially finished with UV-resistant properties). Bonded nylon is great for utility-type projects, like tool belts, camping equipment, and sports gear. Pay special attention to how nylon is finished to determine its properties.

Silk: This thread is fine, flexible, and strong. It's gentle on delicate fabric because it's not abrasive, nor does it create visible holes. It holds dye well and is known for producing long-lasting, vibrant colors. Silk is washable, lint-free, and comes in a variety of weights. Being an animal-based fiber, it tends to work well with both silk and wool fabric. Silk is often used in fine tailoring, fine embroidery, sewing on buttons, and when finishing the edges of buttonholes.

Wool: This animal-based thread is created from the fleece of sheep and can be spun into fine, medium, and thick weights. Wool thread is commonly used during hand needlework, but specially designed, fine wool threads can be used in machines. It's especially useful when embroidering thicker fabric and when you want your design to have great texture. It also dyes well, creating deep, rich tones. Wool thread is soft, durable, and warm and works wonderfully in the construction of wool clothing and blankets. However, a high-quality wool thread is expensive. Wool will wick away moisture, but once it's saturated, it loses much of its strength.

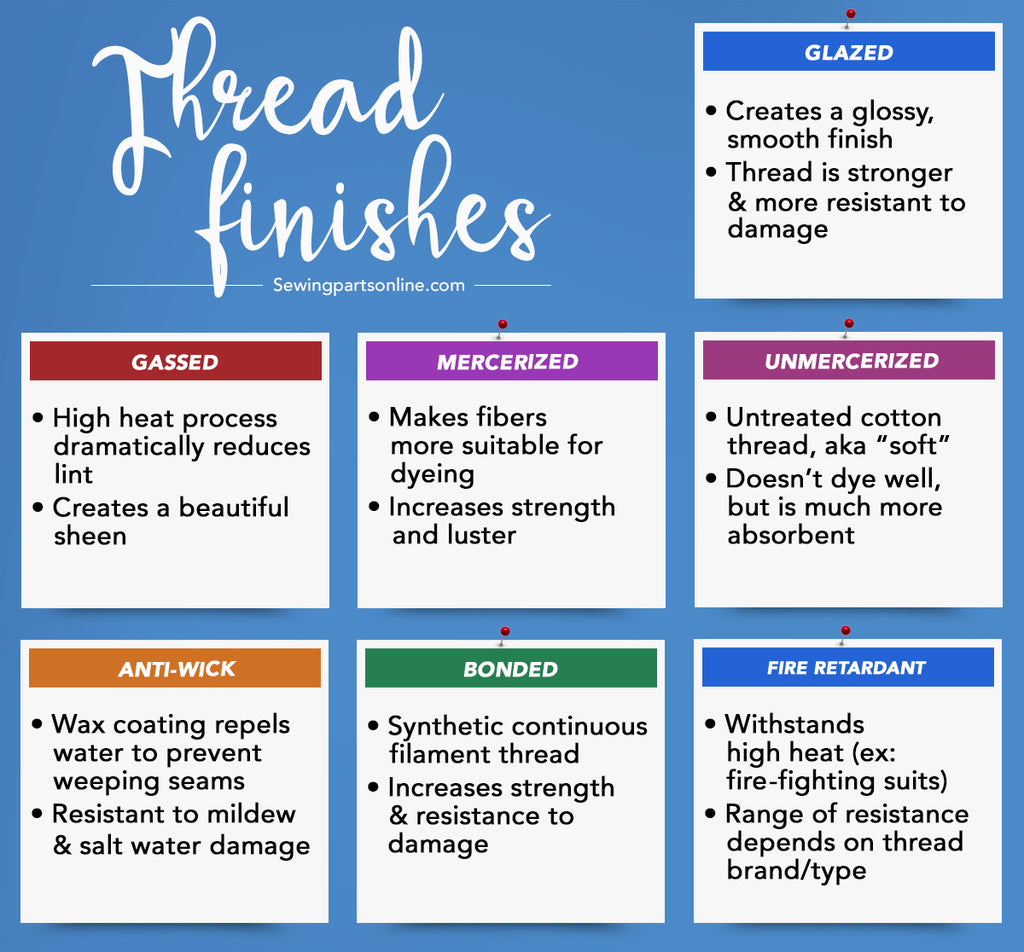

Thread Finishes

After the thread has been spun, it needs to be given a "finish". The purpose of a "finishing" thread is both practical and decorative. By finishing the thread, it's given protective properties, allowing it to better withstand heat, water, and tension. In addition, many finishes make it easier to pass the thread through the fabric and can create visual effects, such as a silky shine or a soft sheen.

Anti-wick: This finish helps the thread repel water. It prevents "weeping" seams and is resistant to mildew. It's also resistant to saltwater damage. You commonly see this thread used in sailing and other outdoor hobbies.

Bonded: Bonded thread has a special resin applied to create a tough, but smooth, protective casing. This is most often applied to nylon and polyester thread with multiple filaments, like corespun polyester and smooth multifilament thread.

Glazed: Thread is coated with wax, starch, and other chemicals to create a glossy, smooth finish. This process protects the thread from breakdown and damage, but it can also gum up your machine. Make sure to frequently clean your machine when using a thread with this type of finish.

Gassed: This type of finish uses high heat to reduce the amount of fuzz and lint created by the thread. This creates a smooth finish and improves performance.

Mercerized: This process coats the yarn, making it stronger and increases its luster. It's easier to dye and produces beautiful, rich colors. It's also resistant to mildew. However, it is less absorbent than an unmercerized thread. This process also preshrinks cotton thread.

Unmercerized (soft): The fibers are left untreated and remain in their natural form (relatively speaking, of course). An unmercerized thread is very absorbent, making it more ideal for towels, dishcloths, etc.

Fire Retardant: This thread is able to withstand extreme heat. The special coating is essential for firefighting gear and race car suits. It's even used in children's bedding and mattresses.

How Thread is Measured

There are many different ways in which thread is measured and categorized. You've probably heard of thread "weight", but have you also heard of "Tex"? Or seen 40/3 printed on the spool and wondered, "what does that mean?" It's confusing because different brands will use different measuring methods. Because there is such a lack of consistency and no agreed-upon "industry standard", thread companies often go by their own rules.

We'll touch base on the 5 common measurements. However, take all measurements with a grain of salt and use your own experience and judgment.

1.) Thread Weight: How many kilometers of 'x' thread is needed to equal 1 kilogram?

When dealing specifically with weight, the smaller the number, the heavier/thicker the weight. The higher the number, the lighter/finer the thread. So, a thread listed as 30wt is heavier than a thread listed as 50wt because it only takes 30 kilometers (of said thread) to reach 1 kilogram. Most all-purpose sewing machine thread is 40wt. It's important to note that this measurement is really only used in the US and, again, isn't 100% accurate, because not all companies actually follow the above formula. Yet, they still label the thread as 40wt. Long story short, some brands borrowed measurements from other brands, not realizing it was an entirely different measurement technique. Oops.

2.) Denier: How many grams do 9000 meters of 'x' thread weigh?

You may also see thread measured in Denier. For example, you may see a thread marked as Den 225. This number is saying that the weight of 9000 meters of 'x' thread is equal to 225 grams. The larger the number, the heavier/thicker the thread. The lower the number, the lighter/finer the thread. Most medium-weight thread is Denier 225.

3.) Tex: How many grams do 1000 meters of thread weigh?

This measurement is determined by how much 1000 meters of thread weighs in grams. For instance, if 1000 meters of thread weighs 25 grams, then the thread will be listed as Tex 25. The higher the number, the heavier/thicker the thread. The lower the number, the lighter/finer the thread. Generally, a medium-weight thread is between Tex 27 and Tex 35.

4.) The Number Standard:

The Number Standard is tricky, I'm still not sure how the numbering is determined. I do know that the lower the number, the thicker the thread. For instance, No. 50 is thicker than No. 100 thread. Make note that No. 100 is not the same as 100wt. It's like kilometers and miles. They're completely different forms of measurement.

5.) Composition Labeling:

You may have also seen thread measured as No. 50/2 or No. 30/3. This type of measurement is describing two different characteristics. The first number is meant to convey the thickness/heaviness via the Number Standard. The second value describes the number of plies (strands of yarn) used to create the thread. For instance, No. 50/2 means Number 50 thread composed of 3 plies. Again, this isn't an exact science. Some companies may use Denier weight or Tex weight in place of the Number Standard.

Now that you know how the thread is weighed, let's talk about how its strength is determined. There are 4 common methods of testing strength:

Tensile Strength: This is determined by how much force (in grams or kg) is needed to break the thread. A higher tensile strength would indicate a stronger thread because more weight is needed to break it.

Tenacity: This is determined by the maximum tensile force divided by linear density (say what?). The takeaway here is that you want the thread tenacity to match the fabric strength or slightly weaker. The exception is performance products. The thread should always be just as strong or stronger than the fabric.

Loop Strength: This is tested by looping a thread strand through a loop of the same thread and breaking it. This measurement indicates the brittleness of the thread and overall stitch strength.

Knot Strength: This term indicated how much load the thread can withstand when knotted before breaking.

Confused? We don't blame you. Half of this leaves us scratching our heads. At the end of the day, trust your sewing experience and use what you've learned from this guide to determine which thread to choose. We'll continue to update this as new types of thread are engineered, so be sure to bookmark this article and check back frequently. Happy sewing!